Zhejiang Hongxiang Multi-hole Cable Gland: Deepening Details to Empower Industrial Connections and Efficiently Solve Multi-cable Wiring Challenges

Zhejiang Hongxiang Multi-hole Cable Gland: Deepening Details to Empower Industrial Connections and Efficiently Solve Multi-cable Wiring Challenges

In core fields such as industrial automation, new energy, and rail transit, the safety, stability, and wiring standardization of cable connections are directly related to the operational efficiency and maintenance guarantee of the entire electrical system. Especially in scenarios with centralized multi-cable access, such as PLC control cabinets, new energy equipment, and rail transit cabinets, traditional single-hole connectors generally have problems such as messy wiring, insufficient protection performance, and low installation efficiency, which may easily lead to risks such as equipment failures and inconvenient maintenance. With years of experience in the connector industry, Zhejiang Hongxiang Connector Co., Ltd. is based on the actual needs of industrial sites, abandons homogeneous parameter stacking, and focuses on core pain points to develop and manufacture multi-hole cable glands. With the core advantages of standardized wiring, reliable protection, and efficient installation, it provides high-quality solutions for industrial connections in various industries and has been recognized and favored by a large number of engineering and technical personnel and procurement departments.

Breaking Through Homogenization Barriers: Core Competitive Advantages of Hongxiang Multi-hole Cable Glands

There are many types of multi-hole cable gland products on the current market, but some products have problems such as insufficient adaptation flexibility and disconnection between protection performance and actual working conditions. Relying on years of industrial technical accumulation, Zhejiang Hongxiang's multi-hole cable glands carry out R&D and optimization based on actual application scenarios, focus on core pain points to provide practical solutions, and their core competitiveness is prominent.

2-8 Hole Multi-specification Adaptation for Standardized Wiring Management

To meet the differentiated adaptation needs of different industrial equipment in terms of cable quantity and diameter, Zhejiang Hongxiang's multi-hole cable glands cover a full range of 2-8 hole specifications. They can accurately match scenarios with centralized access of 3-4 thin cables such as sensors and small control equipment, as well as batch wiring scenarios of multiple cable groups for large industrial equipment. The product adopts an independent hole design, and each hole can be accurately adapted according to the cable diameter, which effectively avoids problems such as loose cables or difficult installation, significantly improves the standardization of wiring inside the cabinet, provides convenient conditions for subsequent equipment inspection, maintenance, and cable replacement, and reduces the model verification cost during construction and the later maintenance cost.

IP68 High-strength Protection for Complex and Harsh Working Conditions

Industrial sites generally face complex working conditions such as rain, sun exposure, acid-base corrosion, salt spray erosion, and vibration. As a key protection node of the electrical system, the protection performance of the cable gland directly determines the stability of the system operation. Zhejiang Hongxiang's multi-hole cable glands adopt a high-standard protection design, which has passed actual measurement and verification to reach the IP68-10 bar pressure protection level. Within the specified installation range, combined with the special O-ring tightened and fixed, it can effectively block the intrusion of moisture, dust, oil, and other impurities, providing a reliable protective barrier for the internal cable connections.

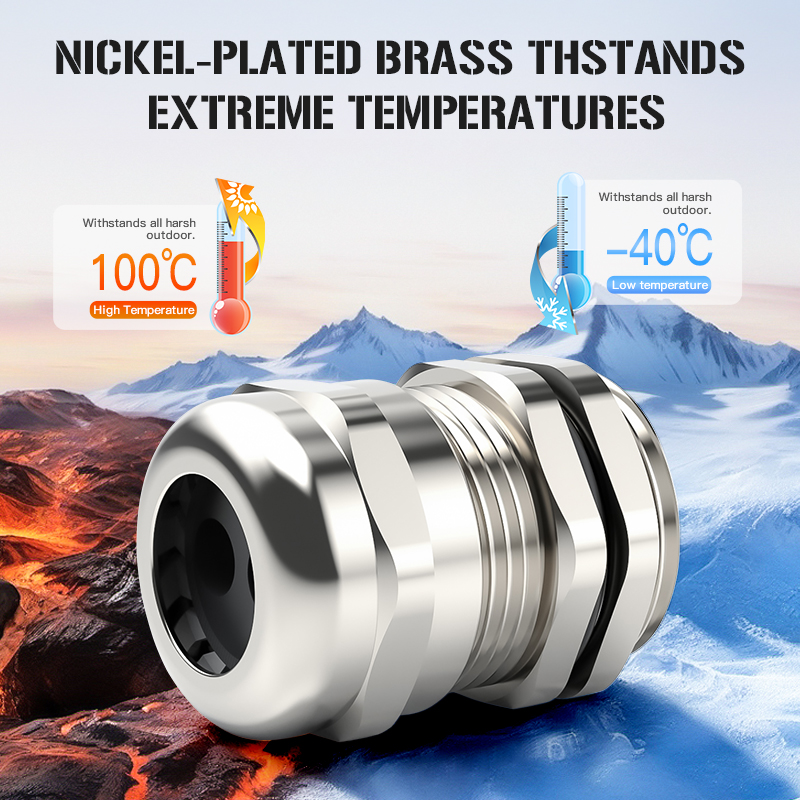

The product strictly controls quality standards in material selection to ensure adaptation to complex industrial working conditions: the main body of the connector is made of nickel-plated brass, which has excellent corrosion resistance and impact resistance, and can be stably used in harsh environments such as salt spray and high dust for a long time without rusting or deformation; the clamping part is made of nylon plastic (PA), which balances structural strength and flexibility, not only realizing the firm fixation of cables but also avoiding damage to the cable sheath; the seal and O-ring are made of nitrile rubber (NBR), which has excellent elasticity and weather resistance. Combined with the special clamping claw and clamping ring structure with concave-convex interlocking, it not only enhances the sealing effect but also has reliable tensile performance, effectively preventing the connector from loosening due to external pulling of the cable.

The product has a wide temperature adaptation range, which can meet the application needs of different regions and scenarios: the static operating temperature range is -40℃ to 100℃, and it can withstand instantaneous high temperatures of 120℃ for a short time; the dynamic operating temperature range is -20℃ to 80℃, which can stably adapt to working conditions with large temperature differences such as cold winters in northern China and high-temperature industrial workshops, ensuring stable and reliable connection performance and protection effect.

Complete Compliance Certifications and Efficient and Convenient Installation

To ensure product compliance and safety, Zhejiang Hongxiang's multi-hole cable glands have passed a number of international authoritative certifications such as European CE certification, ROHS certification, and REACH certification. Both environmental protection indicators and safety performance meet international standards, which can meet the application needs of domestic and foreign markets, provide reliable guarantee for enterprise procurement, and are suitable for various business scenarios such as domestic sales and export.

The product adopts a compression head assembly structure design, which simplifies the installation process. No professional and complex tools are required, and installation and fixing operations can be completed with conventional wrenches, which effectively improves on-site construction efficiency and reduces the operation threshold for construction personnel. At the same time, the product is compatible with various thread specifications such as Metric, PG (German standard thread), NPT (American standard thread), and G (BSP thread), which can be directly adapted to different equipment interface standards without additional adapter components, ensuring smooth and efficient construction processes.

Deeply Rooted in Multi-industry Applications to Build a Solid Guarantee for Industrial Connections

The core value of industrial products lies in the realization of actual application efficiency. With stable and reliable performance and high-quality application experience, Zhejiang Hongxiang's multi-hole cable glands have been widely used in many core industries through word-of-mouth communication and have become one of the core connection components of various key equipment.

In the field of industrial automation, the product adapts to the multi-cable connection needs of core equipment such as PLC control cabinets, servo motors, and sensors. Through standardized wiring and reliable protection, it ensures the continuous and stable operation of automated production lines and reduces the risk of shutdown caused by cable failures; in the new energy field, it is applied to the wiring systems of photovoltaic inverters, outdoor charging piles and other equipment, which can effectively resist the impact of outdoor rain, ultraviolet radiation and other environmental factors, ensuring the safe power generation and charging operation of new energy equipment; in the field of rail transit and shipbuilding, relying on excellent vibration resistance and salt spray corrosion resistance, it extends the service life of equipment and reduces the labor and material costs of later maintenance; in the fields of chemical industry and sewage treatment, it can effectively resist the erosion of acid-base solutions, oil and other corrosive media, prevent equipment failures caused by connector corrosion and failure, and ensure the continuous development of production.

Scientific Selection Guide: Accurate Adaptation to Scenario Needs

To help users make accurate selections, avoid procurement misunderstandings, and combine product characteristics and industry application experience, the following three core selection suggestions are sorted out to help users achieve accurate scenario adaptation and cost optimization:

First, select according to cable parameters: Match the corresponding specification and model according to the actual number of connected cables and the diameter of a single cable. For example, cables with a diameter of 1.2-3mm can be adapted to the HX-NPM20 series products, and cables with a diameter of 3-6mm can be selected from the HX-NPM32 series products to avoid resource waste caused by blindly selecting large-size models.

Second, select according to equipment interface: Confirm the thread type of the equipment interface in advance, and select the matching product model according to different thread specifications such as Metric, German standard, American standard, and BSP, so as to avoid increasing adapter costs and construction complexity due to thread incompatibility.

Third, select according to working conditions: Standard models can be used in conventional environments such as ordinary workshops; for harsh working conditions such as outdoor, high temperature, and strong corrosion, focus on the product's temperature adaptability and material corrosion resistance. For special scenario needs, Zhejiang Hongxiang can provide customized solutions to ensure product adaptability and application effect.

Conclusion: Empowering High-quality Industrial Development with Professional Quality

As a key basic component of industrial electrical systems, cable glands, although small in size, have an important impact on the overall safe and stable operation of the system. Zhejiang Hongxiang Connector Co., Ltd. has always adhered to the development concept of "quality first, demand-oriented", and has been deeply engaged in the connector field for many years. It abandons the extensive development model of "pursuing scale without refinement" and focuses on the segmented track of "focusing on refinement", continuously polishes product details and improves product core competitiveness.

As one of Zhejiang Hongxiang's core products, the multi-hole cable gland fully reflects the enterprise's R&D concept of "taking user needs as the core". With solid material selection, reliable protection performance, and efficient installation experience, it provides practical solutions for industrial connection scenarios in various industries. In the future, Zhejiang Hongxiang will continue to deepen industrial technology R&D, closely follow the development trends of the industrial field and changes in user needs, continuously optimize the product system, create more competitive connector products, and build a solid connection guarantee for high-quality industrial development with professional quality.